Asphalt

Emulsion Cold Mix Manufacture

|

Classification

Emulsión cold mixes may be classified as a

function of their:

* use

* composition

* storability

Classification as a function of coated material

use

The name "cold mix"

applies to three types of products

which may be defined as follows:

* cold mixes for maintenance and small

repair works in pavements,

* cold mixes for special uses (especially for

floors in sports centres),

* cold mixes for pavement wearing courses. |

|

The two following manufacturing processes

are available to make these three types of cold

mixes:

|

Stationary

mixing plant

Cold mix, manufactured in a stationary

plant, is normally intended for future use (from

several hours to one month).

On-site manufacture

The cold mixes are manufactured and used

immediately.

Classification as a function of coated material

composition

Open graded cold mixes (O.F.D.)

Open graded cold mixes are manufactured from one

of the following aggregate sizes: 2/4, 4/6, 6/10,

10/14, 10/20. A blend of aggregates from several

sizes is sometimes used. The

percentage of voids in these mixes is greater than

15%. |

Semi-dense graded cold mixes (S.F.D.)

Semi-dense graded cold mixes are manufactured with 0/4, 0/6, 0/10 or 0/14

aggregates. The percentage of voids is between 10 and

15%.

Dense graded cold mixes (D.F.D.)

Dense graded cold mixes are manufactured with the

same type of aggregates as semi-dense graded cold mixes but their filler

content is higher. The percentage

of voids is less than 10%. As the coating emulsion

has a pure bitumen base, the

storage time for these mixes is very low.

Classification as a function of mix storability

Storable cold mixes

Storable cold mixes or cold mixes for future use (from

one hour to one month) are manufactured in a mixing plant with a continuous

or discontinuous mix of one of the following types:

* mixer with a capacity of approximately 100

tons per day,

* discontinuous mixer, whose capacity is

approximately 200 to 800 tons per day.

* continuous mixer, whose capacity is greater than 500

tons per day.

The source of aggregates depends on the use of cold asphalt:

materials may be calcareous, silico-calcareous or from

solid rock.

Aggregates are made entirely of crushed materials.

The emulsión used has generally a cutback or

fluxed bitumen base.

The percentage of flux depends on the end use of the cold

asphalt, the laying equipment and

the required storage lite. The residual binder content is

a maximum of 5.5%. In the mixing

plant, the aggregates are supplied from separate weigh

hoppers, making it possible to produce the required

grading by adjusting the supply rates.

The binder is stored in a tank and is injected

into the mixer by means of a metering pump. Product

delivery to the customer is in bulk by tipper trucks or

in easy to use small packages (bags or drums) for small

repair works. The product may be bulk coloured.

Laying is by hand, or with a grader or a paver.

|

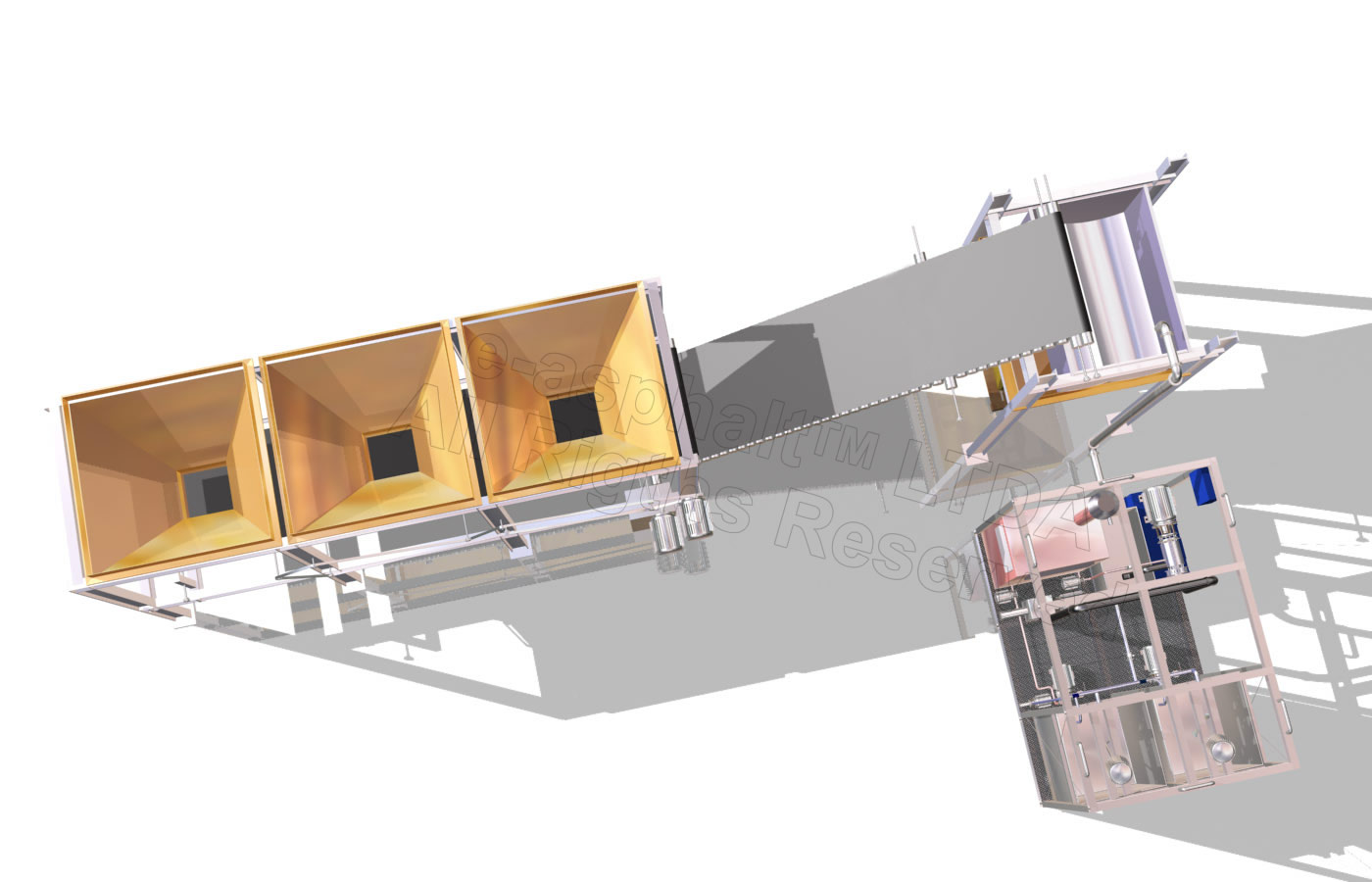

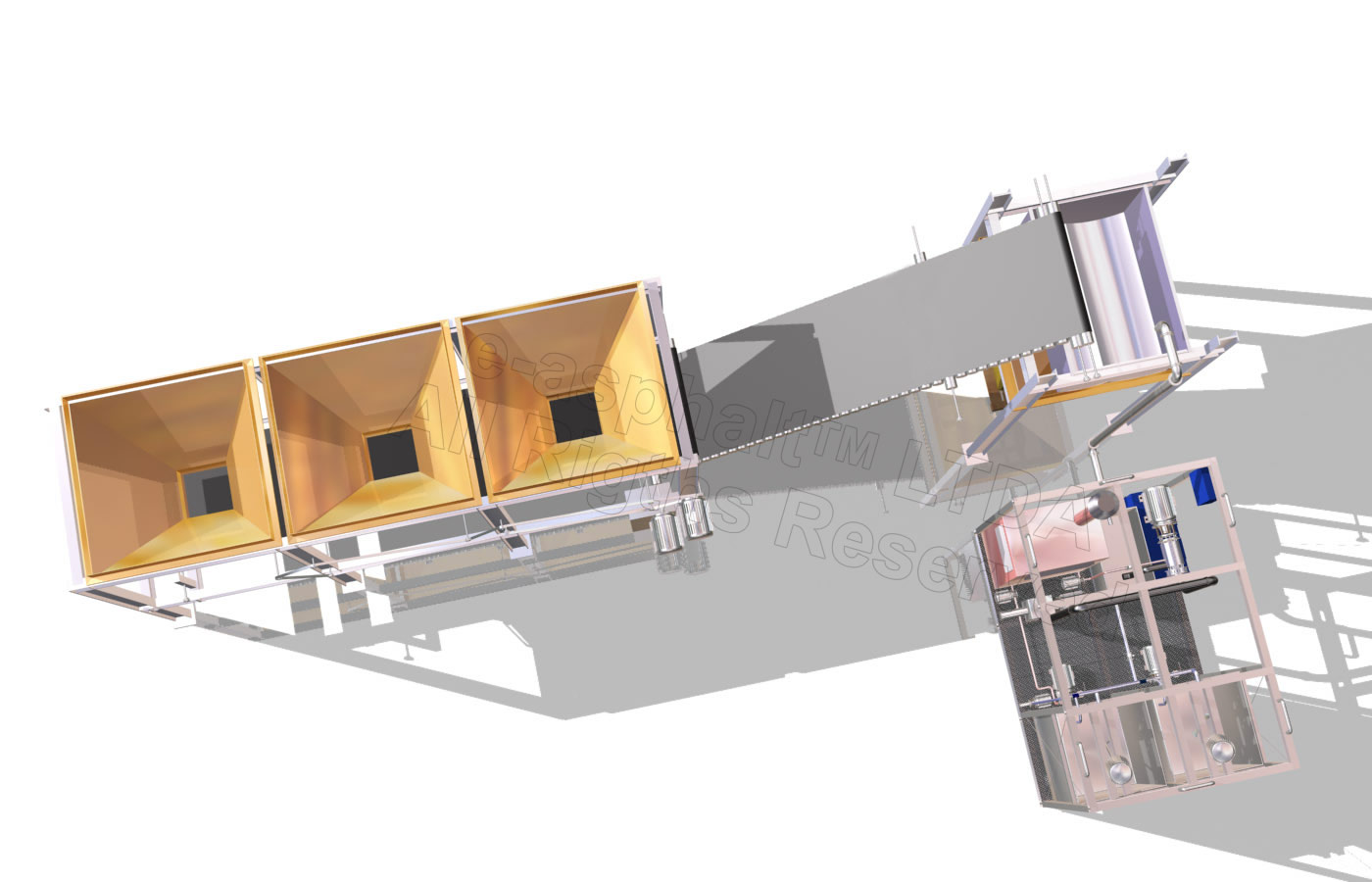

Immediate use or non-storable

cold mixes

These asphalts are manufactured on site in a

mobile mixing plant. This plant consists of a coating

truck when the site work mainly consists of repairs.

In this case, laying is by hand.

The aggregate fed to the mixer is graded at

the quarry. When the cold asphait is for a wearing

course, the plant is of the motopaver type. A mixer

fitted with dosing pumps is used to manufacture the

cold asphalt with the required residual bitumen and

water content. Contents are selected to provide the

required mechanical performances and to facilitate

work. The aggregate fed to the mixer is graded at

the quarry site. |

|

The emulsion used is based

on a pure bitumen which gives the asphalt

high mechanical properties as soon as the breaking water

is expelled.

Laying is by means of:

* either a grader; when the asphalt

is previously placed in calibrated windrows,

* or by means of a vibrating table, similar to

that in a paver, which spreads the cold mix and,

at the same time, compacts it at the outlet from the machine.

e-asphalt.com

will be happy to quote special machines or proyect plant

on receipt of details of composition of the product, etc.

More Information Send Mail to:

info@e-asfalto.com

Copyright © 2005-10 | All Rigths

Reserved. | Home | Buenos Aires Argentina

TELFAX: 005411-4754-9374 / 6351-6288 (whatsapp) / 5931-8727